ZwickRoel High-frequency Testing Machine Vibrophore 100

| Equipment composition |

| A high-frequency testing machine, Vibrophore 100 includes: – Load cell with a capacity of 100 kN. -A set of jaws for clamping cylindrical samples with 4 to 17-mm diameters. -A set of jaws for clamping flat samples thickness from 0 to 10 mm. -Set of supports for three- and four-point bending tests. -Set of compression plates. -Mechanical digiClip extensometer with a gauge length of 25 and 50 mm. -Extensometer for crack growth monitoring. -Software package TestXpert III (for static testing). -Software package TestXpert R (for dynamic testing). |

| Equipment presentation |

| The high-frequency testing machine Vibrophore 100 from ZwickRoell company represents the latest generation of high-frequency pulsators used for static and dynamic testing of engineering materials. The operating principle of the resonance testing system is based on the concept of a mechanical resonator with an electromagnetic drive. The dynamic load is generated by an oscillation system that works when the system operates at full resonance. In this way test frequencies of up to 285Hz are possible, provided the specimens are sufficiently stiff. Static and dynamic testing can be performed in force, displacement or strain control. With the possibility of changing the clamping inserts, cylindrical and flat samples can be clamped in the machine. The mentioned machine also enables bending and compression tests to be carried out. Typical applications of resonant testing systems are material fatigue tests and durability tests on standardised samples and components (for example, pistons, crankshafts and bolts) and the production and quality control of components subjected to dynamic loads during their lifetime, such as concrete and reinforcing steel, as well as quasi-static tensile and compressive tests and fracture mechanics tests, such as: determining the fracture toughness of various engineering materials and monitoring fatigue crack growth to determine the Paris material parameters. |

Equipment Custodians: Assist. Prof. Dr Branko Nečemer, branko.necemer@um.si

ZwickRoel Electrodynamic Testing Machine LTM3

| Equipment composition |

| The electrodynamic testing machine includes: -Load cell with a capacity of 3 kN. -A set of jaws for clamping cylindrical samples with 2.5 to 12-mm diameters. -A set of jaws for clamping flat samples thickness from 0 to 12 mm. -Set of supports for three- and four-point bending tests. -Set of compression plates. -Mechanical digiClip extensometer with a gauge length of 25 and 50 mm. -Extensometer for crack growth monitoring. -Extensiometer for dynamic and static testing in the temperature range -80°C to +250°C. -Software package TestXpert III (for static testing). -Software package TestXpert R (for dynamic testing). |

| Equipment presentation |

| The electrodynamic testing machine LTM is a dynamic machine with a drive based on linear motor technology. LTM is used for dynamic and static testing of materials and components. The low moving mass of the actuator provides ideal conditions for performing fatigue tests with tensile, compressive, and bending loads. The LTM’s wide speed range allows it to be used for dynamic fatigue and quasi-static tests on standard plastic, composite fibre and metal specimens. The oil-free drive combined with ease of installation makes the electrodynamic testing machine ideal for use in biomedical engineering and electronics and for research into the mechanical characterisation of modern engineering materials. The test frequencies, which are up to 100 Hz depending on the test, ensure short test times and with that high specimen throughput. For testing components, the LTM is equipped with a plate with T-slots to which we can easily attach various components, which allows us to have a quick and easy test device. The intuitive operation of testXpert R and testXpert III software makes the LTM truly versatile for industrial purposes and research and teaching at the university level. |

Equipment Custodians: Assist. Prof. Dr Branko Nečemer, branko.necemer@um.si

ZwickRoel Temperature Chamber

| Equipment composition |

| -Temperature chamber -80°C and +250°C. -Liquid nitrogen cooling system. |

| Equipment presentation |

| The temperature chamber for the mechanical characterisation of materials is an important laboratory equipment that enables the testing of materials under various environmental conditions where the materials may find themselves in real applications. The ability to operate within a temperature range between -80°C and +250°C allows researchers and engineers to control the temperature precisely, enabling extensive studies of the mechanical properties of materials at different temperatures. The temperature chamber enables precise maintenance of the desired temperature with high accuracy, ensuring reliable experimental results. Operating from -80°C to +250°C allows materials to be tested in extreme conditions, such as cold environments or high temperatures in specific applications. Using a temperature chamber for the mechanical characterisation of materials allows researchers to understand better the effect of temperature changes on the properties of materials, which is crucial in developing and improving materials for various industrial and scientific purposes. |

Equipment Custodians: Assist. Prof. Dr Branko Nečemer, branko.necemer@um.si

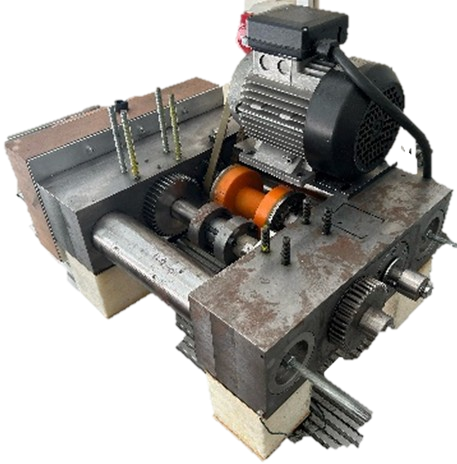

Compact test ring for gear testing

| Equipment composition |

| -AC electric motor. -Timing belt drive -Gear lubrication system. |

| Equipment presentation |

| The test rig is applicable for testing cylindrical gear pairs made of different engineering materials (metals, sintered materials, polymers). The experimental testing is focused mainly on the wear behaviour of analysed gears under different operating conditions (lubricated contact, dry contact, |

Equipment Custodians: Assist. Prof. Dr Branko Nečemer, branko.necemer@um.si